Our Project

We have been working on the realization of our idea since our Focus-Project Focus-Project “Adaptive Helicopter Landing Gear” started nine months ago. On the 30th of May 2017, we were able to present a fully working prototype at the Focus-Roll-Out.

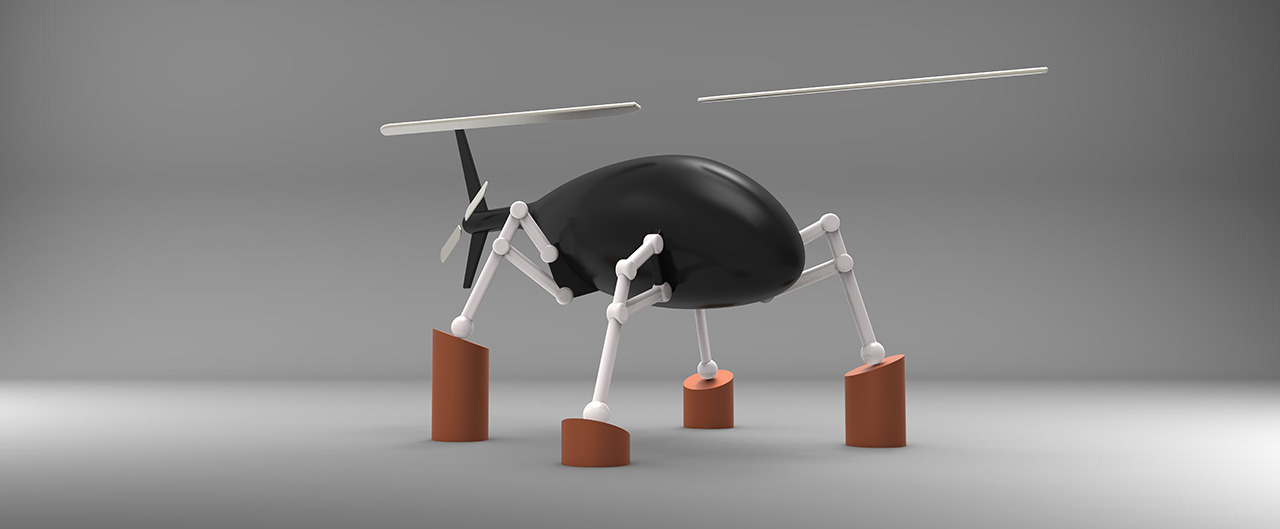

Our Concept

The landing gear consists of four legs with one degree of freedom each. This enables the adaption to the terrain and provides sufficient tilt resistance. This makes landings on hills with slopes exceeding 20° possible. The landing gear also enables overcoming up to 50 cm tall obstacles. We used an unmanned helicopter designed by Aeroscout as a platform for our prototype.

Features

Autonomy

No input by the pilot is necessary during the landing procedure. This is a must for the system, since the pilot is already completely occupied during this stage of flight. With the single “Gear Down” input, the operation of the system is virtually as easy as conventional landing gears.

Dynamics

Each leg is controlled individually, allowing an optimal adaption to uneven terrain. Due to the use of force control, the adaption is fast and smooth.

Modularity

The modular design of the feet enables a quick and simple adjustment for special operation areas such as snow and ice. For easy maneuvering on the ground, the use of wheels is possible as well.

Safety

In the case of a partial or complete system failure, the position of the landing gear is still secured. This is accomplished by the use of safety brakes such as a redundant control unit.

Stability

The system is robust enough to withstand a drop from 35 cm without any damage. This is possible due to the use of high strength materials and a high-performance damper.

Weight

The total weight adds up to 15 kg which is substantially less than other systems with comparable functionality.

Geometry

The animation shows our concept consisting of a parallelogram with adapted side lengths. The lengths were optimized to allow a vertical movement of the foot with as little lateral offset using only one degree of freedom. Thus, the point of contact's lateral movement is negligable while the system compensates the unevenness of the terrain.

Drivetrain

The legs are driven by a custom-built linear actuator consisting of an electric motor driving a ball screw. A brake can stop the movement of the ball screw. In series, a damper is installed to absorb the high loads occurring during hard landings. With an operating weight of only 1.2 kg per leg loads of 300 kg can be carried.

Control

The adaption to the terrain during the landing is achieved with force control. Logging the current induced in the motor enables registering ground contact. On contact, each leg is raised until all legs report contact. Then, the orientation of the helicopter is regulated using an IMU and finally all brakes are closed.

Result

The prototype was tested extensively on the testing setup as well as in flight. Wooden pallets were used as obstacles. All testing scenarios could be completed successfully. The inclination of the rotor after landing could be kept below 5°. Thus, the functionality of the concept was proven effectively.

Outlook

In the next semester, the results will be published. Further work on the system will be conducted by means of semester and master theses. A commercial use of the technology is not yet at hand.

Focus-Project

In the third and final year of the Bachelor’s program in Mechanical Engineering at ETH Zurich, the students can decide between doing a Focus-Project and a Focus-Specialization. The aim of the Specialization is widening the theoretical knowledge in a certain engineering field. Focus-Projects on the other hand allow students to apply the knowledge acquired during the Bachelor’s program to find an optimal solution to a complex problem. This goal is accomplished by tackling the different steps of product development in a practical context.

The complete Focus-Project team is made up of students in Mechanical Engineering and is completed by students from other departments at ETH, the Zürcher Hochschule für Angewandte Wissenschaften (ZHaW) and the Zürcher Hochschule der Künste (ZHdk).

The final goal of a Focus-Project is presenting a fully functional prototype at the Roll-out presentation on the 30th of May. It is however possible and likely that successful and promising projects are further pursued after the Roll-out. This date merely means the end of the Focus-project.

Examples of previous Focus-Projects: